Assembly Procedure PTFE Reusable Fittings

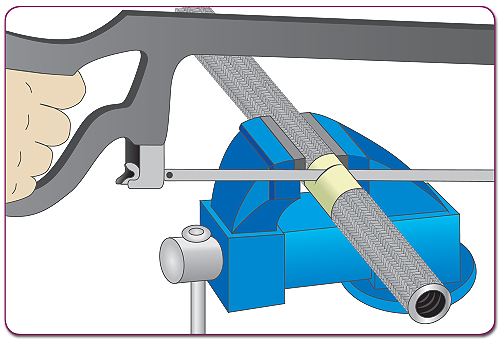

1. Having established the required length, cut the hose with a suitable cut off wheel or fine toothed hack saw blade. To minimize braid flair, wrap the area of the hose to be cut with masking tape.

2. Remove the masking tape and trim any loose braid wires. Remove burrs from inside diameter of the PTFE tube with a sharp knife. Clean the hose to ensure all loose particles and dirt are removed from the bore.

3. Braid tends to flair at one end more than the other, identify the end that has flared less and assemble two sockets back to back from this end.

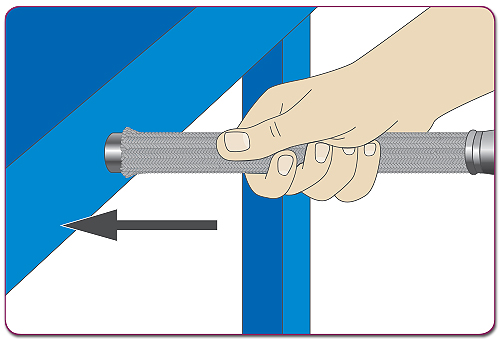

4. Separate the braid from the innercore at each end using the appropriate tool. If the tool is not available, the braid may be loosened by working the hose over the fitting tail.

5. Push the olive over the end of the tube ensuring it goes under the braid wire.

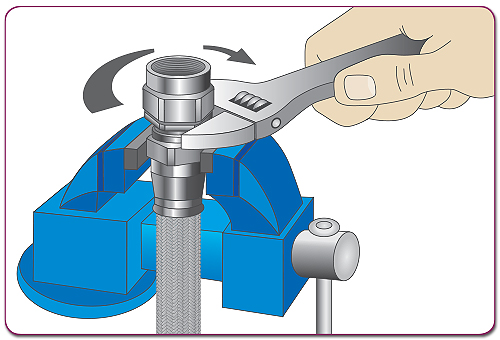

6. Lubricate the fitting and socket threads. Hold the fitting hexagon in a set of vice jaws, push the hose over the tail using a twisting action until the olive is seated against the chamfer on the thread shoulder. Push the socket forward and engage its thread on the fitting thread.

7. Using the appropriate size spanner tighten the two halves of the fitting together until there is a maximum gap of 0.75mm (0.031 inches) between the fitting hex and the socket.

8. Clean the assembly and proof pressure test it to twice the system operating pressure.

NOTE: NEVER loosen fittings once assembled to achieve the desired orientation. ALWAYS use a new olive when reusing an end fitting.

- Assembly Procedure Rigid Tube and FittingsJIS is equivalent to BSP thread (both tapered and parallel). But JIS has a 30° flared seat in the female variant and cone in the male variant (similar to the seat/cone system in JIC fittings)1. Cut the aluminium tube square and deburr the inside and outside diameters (not excessively).2. Assemble fitting by sliding the sleeve and nut over the tubing.3. Flare the tube with the appropriate proprietory flaring tool.

PART NO.

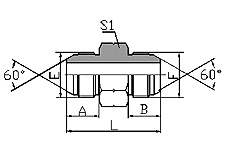

THREAD DIMENSIONS E F A B S1 L P1S-04 G1/4"X19 G1/4"X19 16 16 17 38 P1S-06 G3/8"X19 G3/8"X19 18 18 19 42 P1S-08 G1/2"X14 G1/2"X14 20 20 22 48 P1S-12 G3/4"X14 G3/4"X14 22 22 30 54 P1S-16 G1"X11 G1"X11 24 24 36 59 - Hose Fitting - Torque Tightening ValuesIt is important not to over tighten hose fittings to their mating adapters or housings. Over tightening causes permanent deformation of the fitting seat and will result in the mating adapter sealing face being made concave, this will inhibit repeated reliable use of both the fitting and the adapter.

- Inner Tube:PTFECover: A single Braid Of Stainless SteelTemperature Range: -54oC- +204oC

Hose Part No

Hose ID Hose OD Min Burst Pres Max W.P Min Bend Rad mm mm Mpa Mpa mm 3051 5.1 8 79.3 26.4 63 3067 6.7 9 67.2 22.4 76 3084 8.4 11 62.1 20.7 101 1106 9.5 12.5 69.0 23.0 127 3134 13.4 16.5 48.3 16.1 152 3166 16.6 20 34.5 11.0 178 3198 19.8 23 31.0 10.3 203 3261 26.1 29.5 24.1 8.0 305 High-quality products are the eternal pursuit of our Pehel . We are the manufacturing enterprise that has been founded with modern enterprise management mode. The company's information management all based on the ERP system and carries out ISO9001. Meanwhile, Pehel actively promoted standardized management with 5S in order to achieve a win-win situation between corporate performance and customer benefit.

It was the persistent belief that created the brand. Now the products are not only sold well all over the country, but also exported to Europe, America, Middle East, Southeast Asia and other places.

We Pehel look forward to working with to win a better future with you.

If you need to purchase hydraulic hoses or Hydraulic manufactures, please contact us . Or visit our website:https://www.pehelhydraulic.com/contact.html