Hydraulic Manifold Precision Manufacturing

Hydraulic valves are pressure oil operations with automation components. They are affected by oil pressure control, which is usually associated with electromagnetic pressure control, which is referred to as solenoid coils in combination. A hydraulic valve can be used to turn off an oil, gas, or water pipeline system from a remote control station.

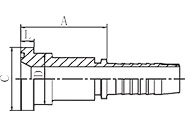

The hydraulic valve manifold in the hydraulic system is used for controlling the flow direction of pressure and flow, so the machining accuracy depends on the hydraulic manifold manufacturing precision to develop the hydraulic valve control characteristics, prior to producing the manifolds the following requirements must be considered:

The surface roughness of the hydraulic valve manifold for mounting valves should be Ra0.4, and the sealing surface of the end plane should be Ra3.2.

Furthermore, the screw fittings' vertical degree of tolerance with the outer surface installation should be at least 8 degrees.

Hydraulic valve blocks are an important component in hydraulic systems because they control the flow of hydraulic fluid. These blocks are made up of a series of valves that can be used to control the system's pressure, flow, and direction of fluid. They are widely used in a variety of industries, including manufacturing, construction, and automotive.

The use of fluid to transfer power from one point to another is how hydraulic systems work. These systems are used in a variety of applications because they are efficient and can generate a high amount of force in a compact space. Hydraulic valves are used to control the flow of fluid within a system and can be operated manually or automatically.

Cartridge valves are a type of hydraulic valve found in hydraulic valve blocks. These valves are intended to be inserted into a block to provide a compact and efficient method of controlling fluid flow. They come in a variety of sizes and configurations, making them suitable for a wide range of applications.

Hydraulic valve blocks are frequently designed with multiple ports, allowing for the connection and control of multiple valves within a single block. This can simplify hydraulic system design, reduce the number of required components, and increase system efficiency.

PEHEL Hydraulic Valve Block Has Unique Technology, Customer Tried A Small Order. Custom manifolds are made to your specifications. PEHEL is the company to contact if you need a manifold, junction block, distribution block, grease block, header block, terminal block, or terminal strip!

When selecting a hydraulic valve block, it is critical to consider the application's specific requirements.When selecting the appropriate valve block, factors such as flow rate, pressure range, and temperature range should all be considered.

Hydraulic valve blocks are sold by a number of manufacturers and suppliers. These blocks are available in a variety of configurations, including ready-made blocks and custom-designed blocks. It is critical to select a reputable supplier who can provide high-quality components that are appropriate for the application.

Hydraulic valve blocks are an important component in hydraulic systems because they provide a way to control fluid flow. These blocks are made up of cartridge valves and can be purchased from a variety of manufacturers and suppliers. To ensure the best performance and efficiency, consider the specific requirements of the application when selecting a hydraulic valve block.