Do You Know How To Use a Hydraulic Hose Crimping Machine?

If you assemble your own hydraulic hoses in the workshop or do field repairs, then you may need a hydraulic hose crimp that allows you to crimp your own fittings. Not only does this allow you to crimp the hose yourself, it also saves time since you don't have to travel to the nearest location and have someone else do it.

Hydraulic hoses are used in a variety of systems and are made to specific lengths depending on where they are installed on the hydraulic components. Before crimping any hydraulic hose, you should make sure you have the correct equipment.

Recommended safety equipment includes: goggles, ear protectors, sturdy protective gloves.

Crimping hydraulic hoses is not difficult. Just follow these steps:

1. Measure the hose length required for your hydraulic system and cut to the appropriate length.

2. Before cutting, for critical hose lengths, be sure to take the cut factor into account when determining the final length. If the edges of the hose are rough, this should be smooth.

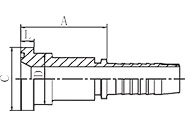

3.Determine the depth of insertion of the hydraulic hoses into the appropriate fittings to ensure that the hydraulic system will not fail after assembly.

4. Choose the correct crimp diameter for each hose before selecting the correct crimp module.

5. Push the hydraulic hose into the crimping machine and through the crimping die until the hose fitting appears over the crimping die. The top of the hose should not be visible above the crimping die.

6. Place the compression ring or collar over the crimping die.

7. Make sure you are wearing safety gear.

8. Turn on the hydraulic hose crimper.

9. The crimping machine then pushes the collar of the crimping die and the machine stops once the collar is at the bottom of the crimping die.