Hose Fittings

Hose fitting is important component used to connect hydraulic circuits, mainly distinguished by three series of threads: metric sandard fitting, inch sandard fitting, and American sandard fitting. There are several hose fittings types:

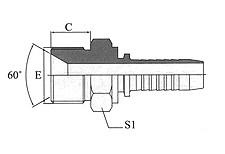

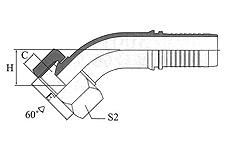

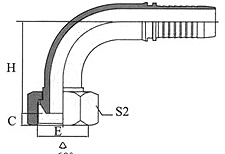

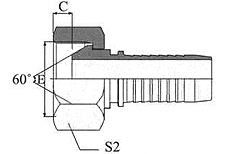

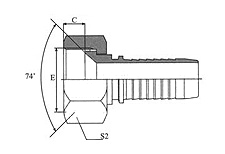

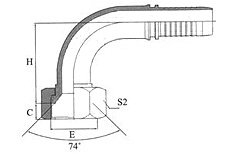

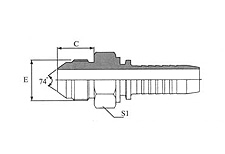

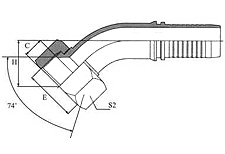

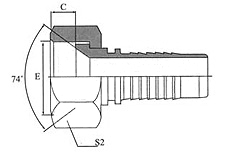

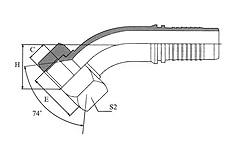

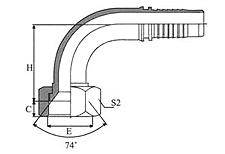

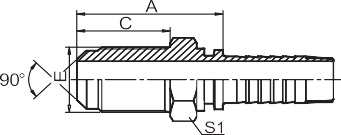

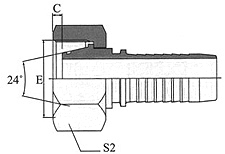

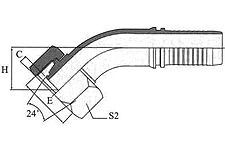

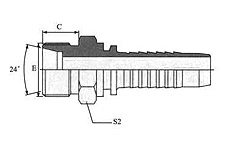

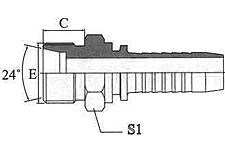

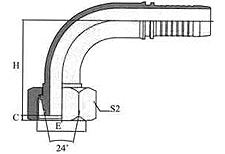

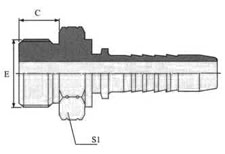

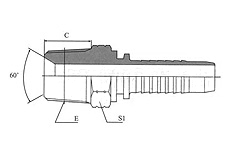

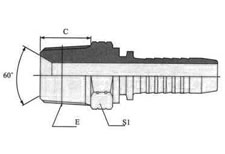

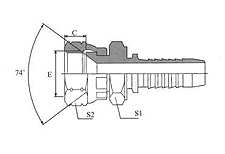

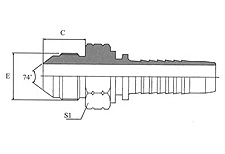

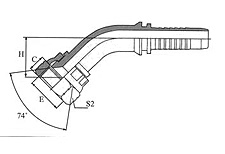

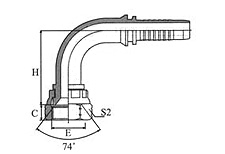

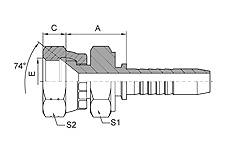

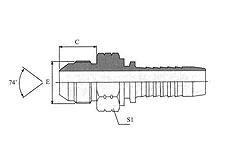

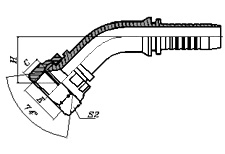

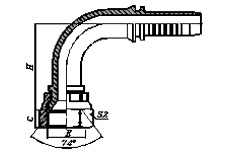

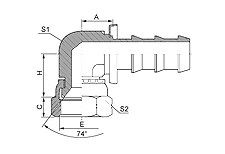

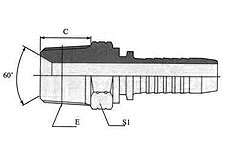

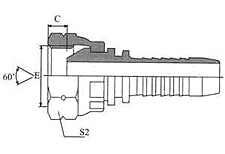

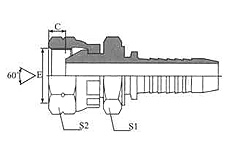

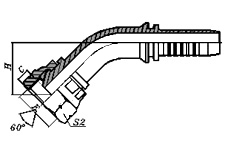

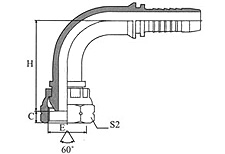

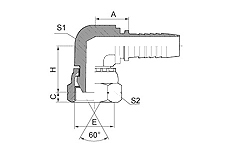

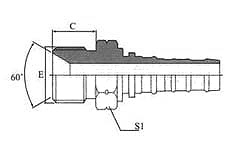

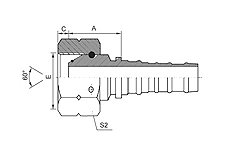

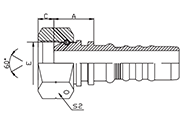

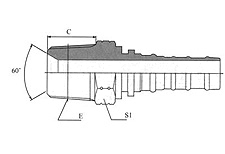

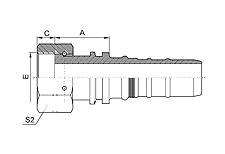

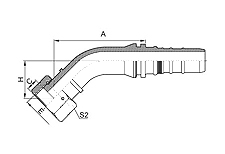

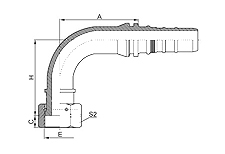

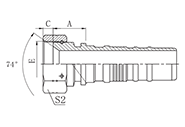

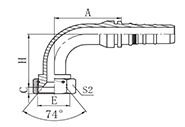

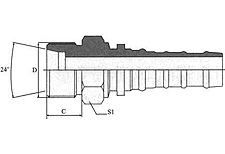

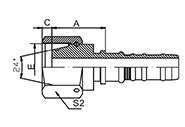

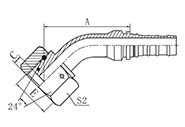

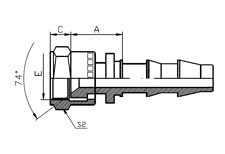

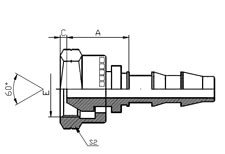

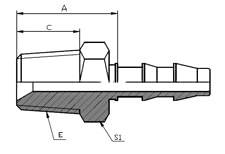

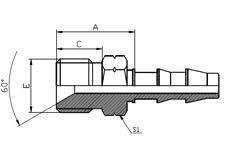

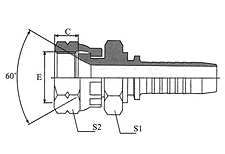

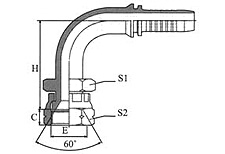

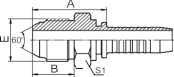

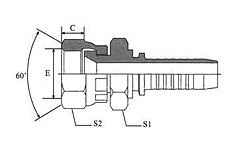

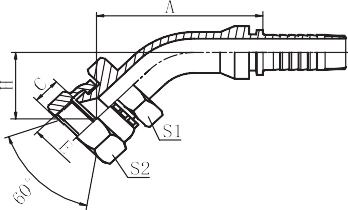

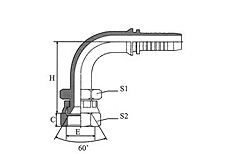

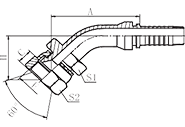

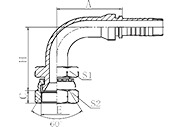

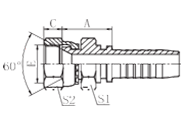

1) Sort by shape: spherical D type, plane A type, 24-degree cone H type, outer cone 60° or 74° G type, inner cone 60° or 74° C type, etc.,

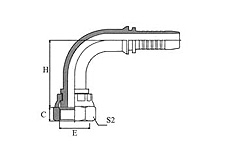

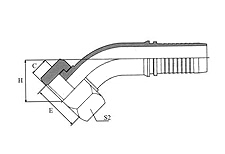

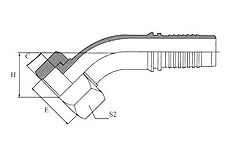

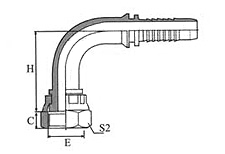

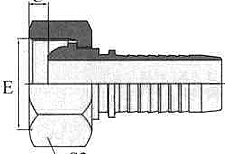

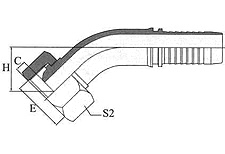

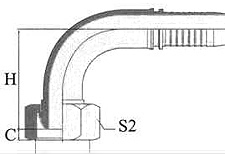

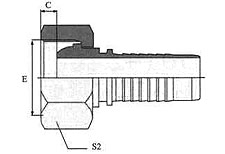

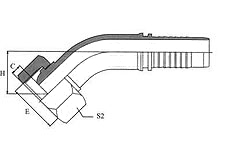

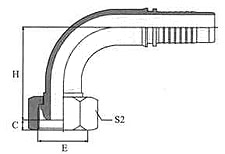

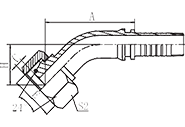

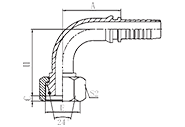

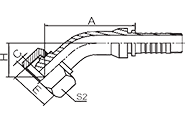

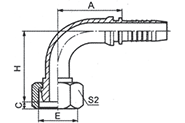

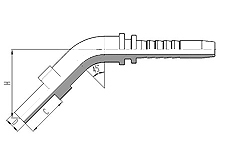

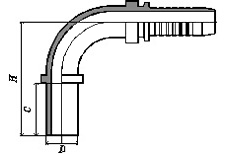

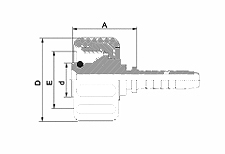

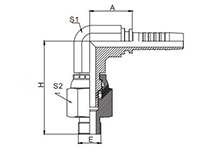

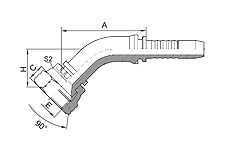

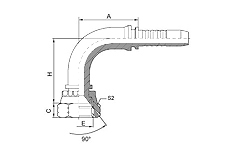

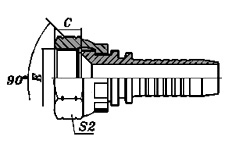

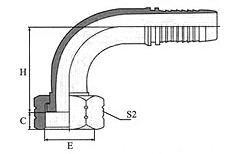

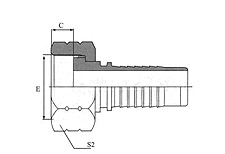

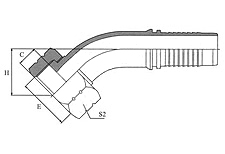

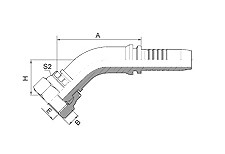

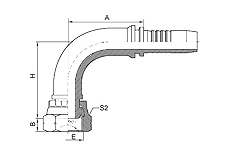

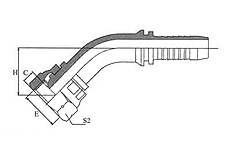

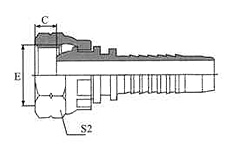

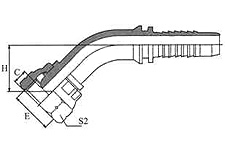

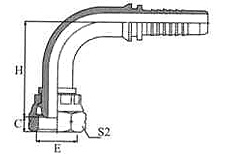

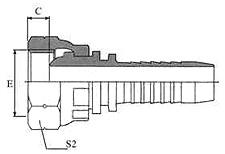

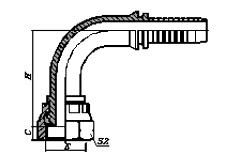

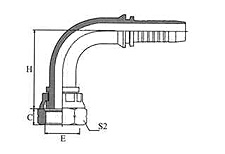

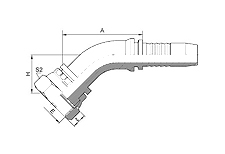

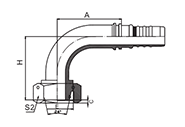

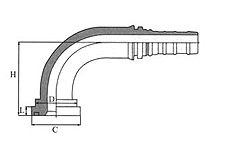

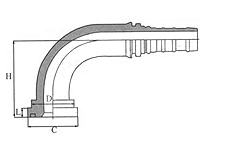

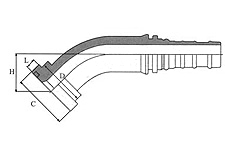

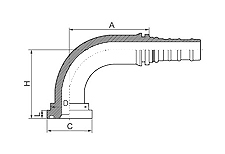

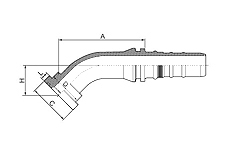

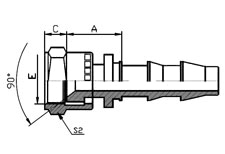

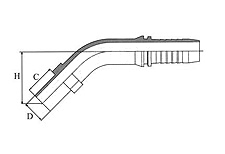

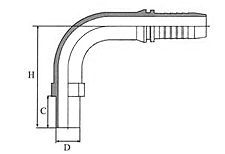

2) Sort by angle: straight cores, Bending core (90°45°25°35° equal angles) , heightening and bending customization hose fittings, etc.

Experience in specialty fittings design can meet all of your hydraulic system requirements.

Please choose our hydraulic fittings online according to your needs!

Table of Contents

- > Hose fittings code and ordering instructions

- > Hose fittings subdivision explanation

- > Select the size of the hose according to the flow rate and flow rate (for reference to the rationality of hose fittings)

- > Compatibility table of hose inner layer, joint material and chemical substances

- > Commonly used hydraulic oil

- > Considerations for choosing hose fittings

- > Hose fittings applications

- > Other accessories

- > FAQ

-

Hose fittings code and ordering instructions

How To Order Hose Fitting

MATERIAL CARBON STEEL COPPER STAINLESS STEEL SIGN - BR SS HOSE DN 3 4 5 6 8 10 12 16 20 22 25 32 40 45 50 64 HOSE DASH -01 -02 -03 -04 -05 -06 -08 -10 -12 -14 -16 -20 -24 -28 -32 -40 BSP THREAD G1/8"28 G1/4"×19 G3/8"×19 G1/2"×14 G5/8"×14 G3/4"×14 G1"×11 G1.1/4"×11 G1.1/2"×11 G2"×11 BSPT THREAD R1/8"28 R1/4"×19 R3/8"×19 R1/2"×14 R3/4"×14 R1"×11 R1.1/4"×11 R1.1/2"×11 R2"×11 NPT THREAD RZ/8"27 Z1/4"×18 Z3/8"×18 Z1/2"×14 Z3/4"×14 Z1"×11.5 Z1.1/4"×11.5 Z1.1/2"×11.5 Z2"×11.5 JIC THREAD 7/16"×20 1/2"×20 9/16"×18 3/4"×16 7/8"×14 1.1/16"×12 1.5/15"×12 1.5/8"×12 1.7/8"×12 2.1/2"×12 FLANGE SIZE 1/2" 3/4" 1" 1.1/4" 1.1/2" 2" DASH -02 -04 -05 -06 -08 -10 -12 -16 -20 -24 -32 Note:The dash of metric thread accords with the O.D of thread. -

Hose fittings subdivision explanation

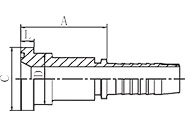

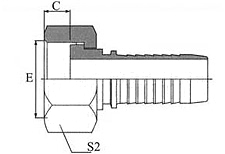

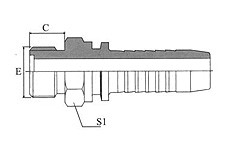

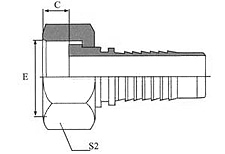

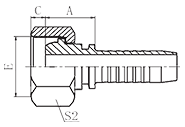

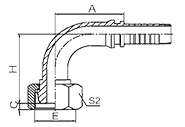

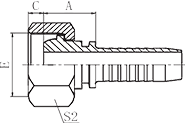

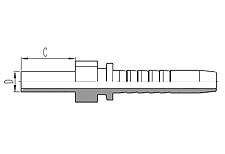

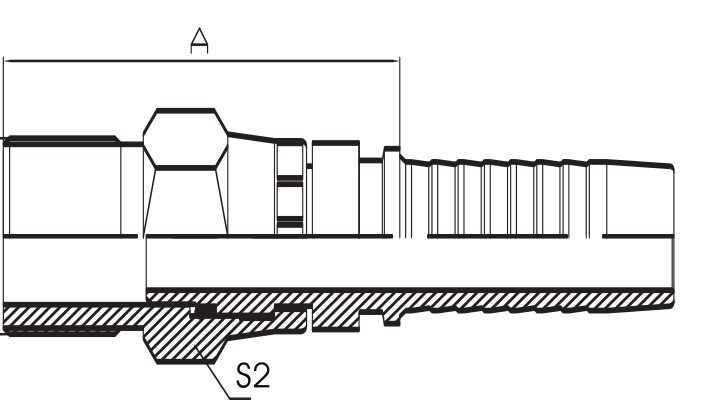

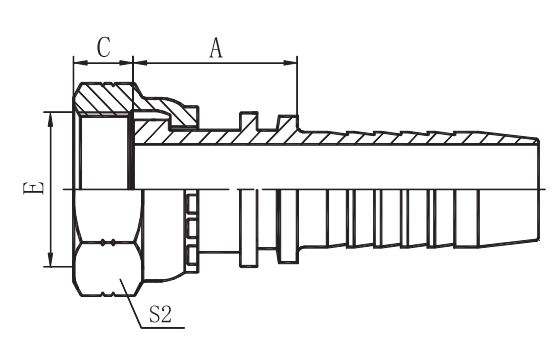

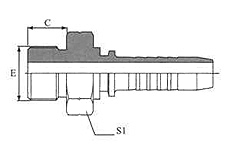

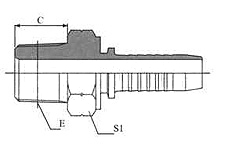

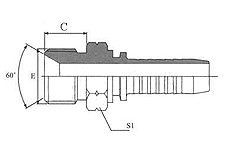

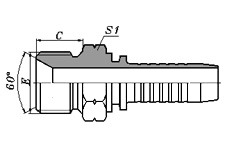

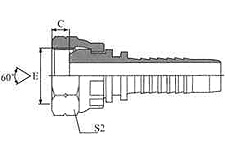

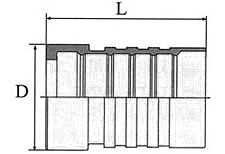

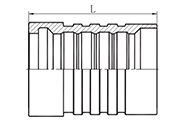

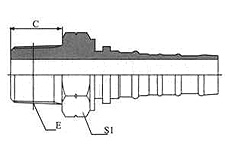

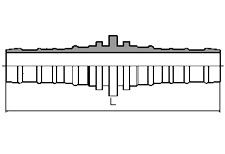

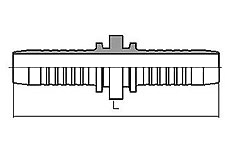

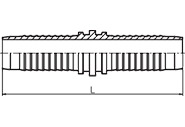

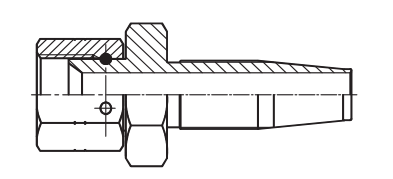

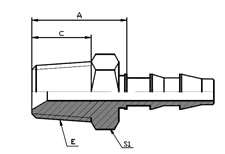

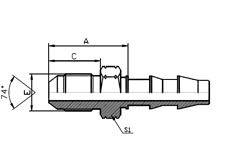

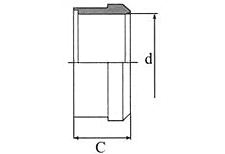

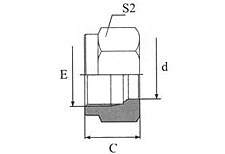

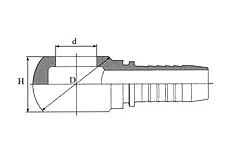

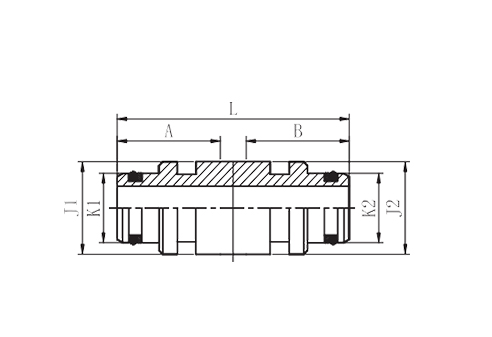

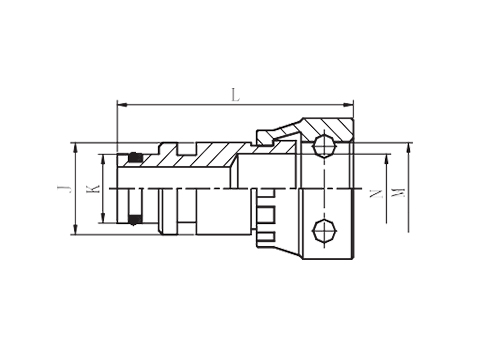

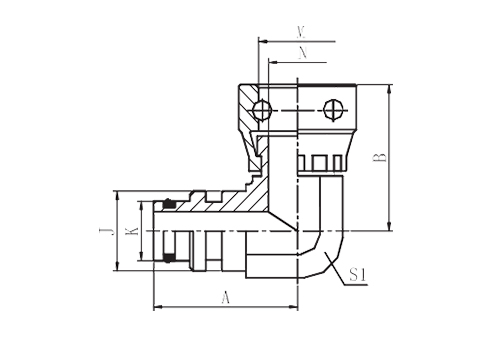

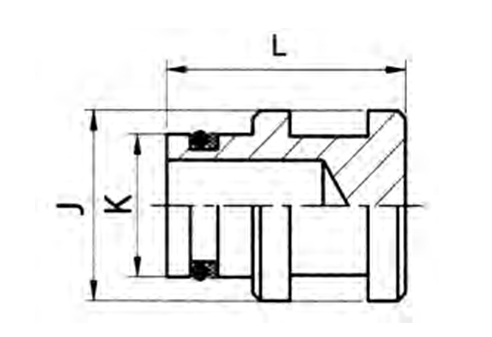

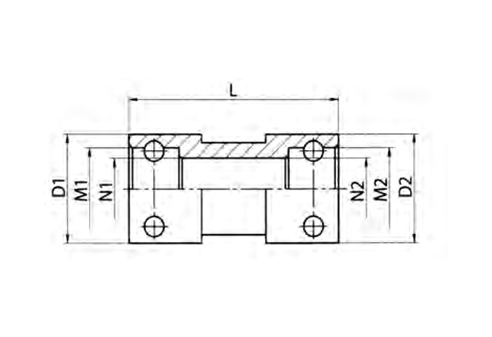

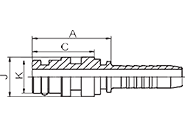

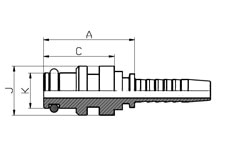

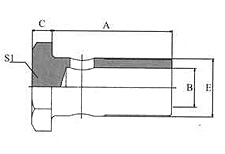

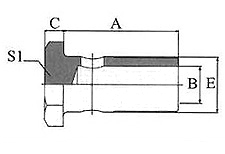

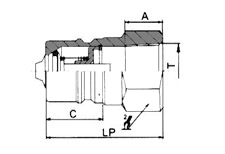

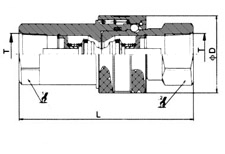

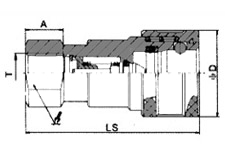

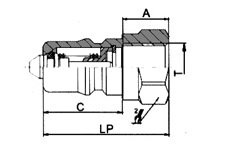

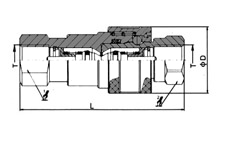

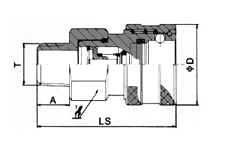

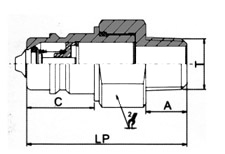

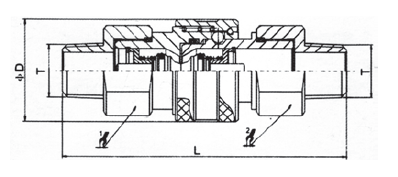

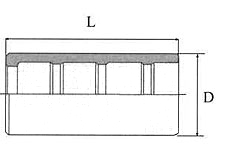

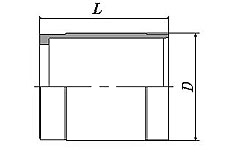

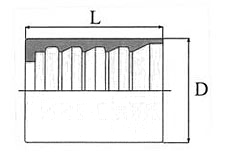

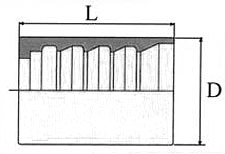

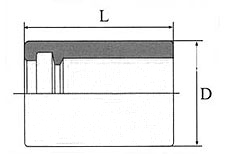

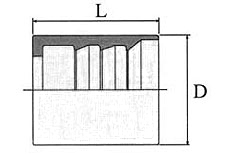

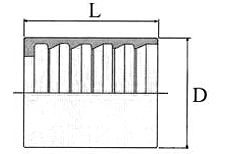

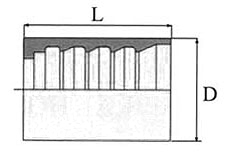

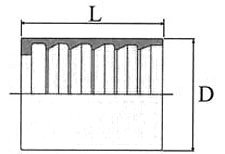

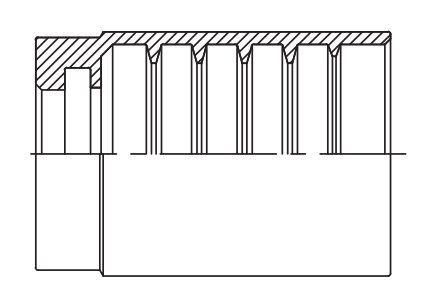

Schematic diagram of common hose fitting tail (matching connection end with rubber hose)

Note: Please confirm the rubber hose information before ordering and select the appropriate core tail connection!

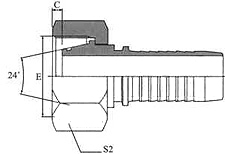

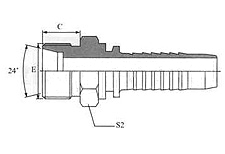

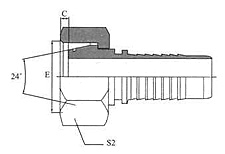

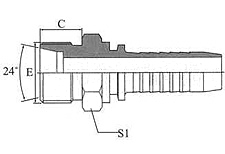

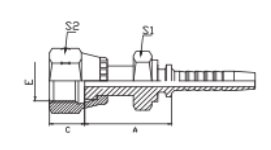

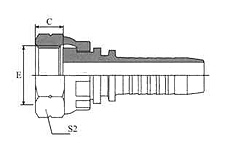

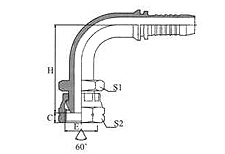

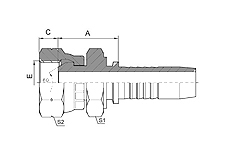

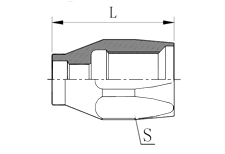

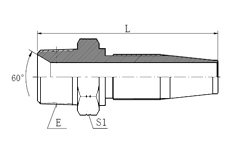

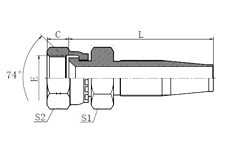

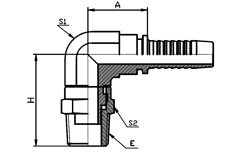

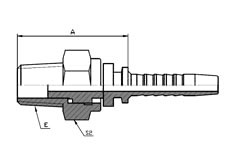

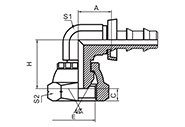

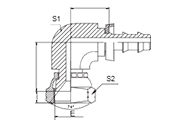

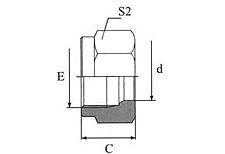

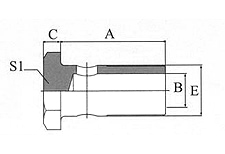

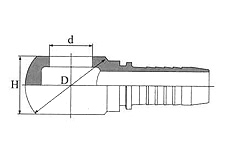

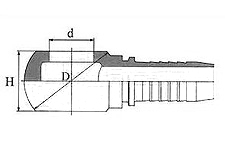

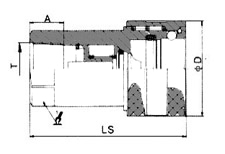

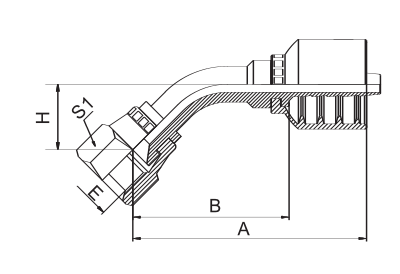

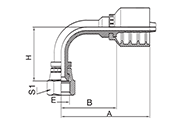

Schematic diagram of common hose fitting head (connecting end with oil port or butt joint)

M metric thread series

G Inch thread series

U American thread series

Other head forms

Note: Please confirm the interface information before ordering and then select the appropriate head connection mode!

-

Select the size of the hose according to the flow rate and flow rate (for reference to the rationality of hose fittings)

When selecting the appropriate hose size, refer to the following figure for calculation, and then match the relevant hose fitting according to the hose size and the butt joint!

You can calculate the proper hose size according to the liquid flow rate and liquid velocity.

To calculate the proper size of rubber hose, just draw a straight line to connect the known flow rate and flow rate. This straight line in the figure and the central one The intersection of the area inside the strip is the diameter value of the rubber hose that should be selected. If no suitable value is found, select the diameter DN Maximum. Use the recommended speeds in the inflow and return pressure systems so that the best operating conditions are always obtained.

-

Compatibility table of hose inner layer, joint material and chemical substances

-

Commonly used hydraulic oil

The hydraulic connector is used to seal the hydraulic oil or fluid in the system. Therefore, fittings shall be compatible with the fluid used. The hydraulic oil provides energy to the system so that the machine can perform its work. There are different types of hydraulic media on the market.

· Petroleum based fluids: Petroleum or mineral based fluids are the most commonly used hydraulic fluids. Additives in these fluids prevent rust and oxidation, wear, corrosion, and extreme pressure. These fluids are generally of high quality, low cost and can be widely used.

· Water based fluids: These fluids have a high moisture content and are therefore used for fire protection. They are provided in the form of water in oil lotion, oil in water lotion and water glycol mixture. They are more expensive than petroleum based fluids and have lower wear resistance.

· Synthetic oils: These oils are man-made and have the advantages of fire protection, low friction and thermal stability. Because of their excellent lubricating properties, they are ideal for high temperature and high pressure applications. However, they are more expensive than petroleum based liquids and may be slightly toxic.

-

Considerations for choosing hose fittings

Before you select the correct hose fitting for your application, you should consider the following situations:

· Main material: the material of hose fitting shall be suitable for hydraulic oil and working environment. The most commonly used main materials are carbon steel parts (grade 20 # 35 # 45 #, etc.), and special materials such as stainless steel/brass/aluminum are also available in special environments. Please inquire and place an order to explain in advance.

· Auxiliary materials: O-ring/rubber gasket/composite gasket, etc. are common seals of hydraulic joints, and NBR (nitrile rubber) and special fluorine rubber are main materials. Please inquire and place an order to explain in advance.

· Surface treatment: the surface of the hydraulic connector is usually galvanized/blackened/phosphatized for carbon steel parts, and other stainless steel parts are pickled or electrolyzed/brass pickled/aluminum parts oxidized.

· Temperature: the general temperature range of hydraulic pipeline is - 40 ℃~+100 ℃. Is it suitable for your temperature range.

· Pressure: hydraulic hose and hose fitting shall be used together. Please confirm the pressure range of rubber hose and connector, including pressure peak. Operation beyond this range or improper matching will cause damage to the connector.

· Assembly: the hydraulic connector is matched with the connecting product. If the supplier is not the same manufacturer, attention shall be paid to:

※Poor sealing may exist when the materials of hose fittings/transition joints and other connectors are inconsistent

※Whether the effective length of the connecting thread matches, different manufacturers may have differences

※When the supplier of hose fitting and sleeve is different, the matching may be inconsistent -

Hose fittings applications

Hydraulic unions are used for pipes and pipes with hydraulic hoses in the following applications:

Factory Applications

Construction Machinery

Construction And Mining Equipment

Agricultural Equipment

Pipeline Application

Oil And Gas Industry

-

Other accessories

Are you looking for other accessories not discussed in this article? Read our other supporting products and related information

-

FAQ

What is a hydraulic fitting?

Hydraulic fittings are used to connect hydraulic hoses to components such as hydraulic cylinders, pipes, tubes or different types of hydraulic hoses. Different types of hydraulic fittings allow fluids to flow, change direction, divert or mix.

What does SAE stand for in Hydraulic Fittings?

SAE stands for Society of Automotive Engineers, an organization that sets standards and develops technical information and expertise. on hydraulic fittings. Hydraulic fittings are usually sealed on threads or by using an O-ring.

How to install hydraulic hose fittings?

Start by selecting the appropriate hose fittings and hydraulic hose for your application and cutting the hose to the desired length. Insert the corresponding socket joint into the hose to match and complete the crimping. Clean components to ensure debris does not enter the system and perform a 1.5-2x pressure test.

How are hydraulic joints sealed?

Hydraulic fittings are self-sealing, such as SAE flange fittings, by using O-rings or by using thread sealants.

-

PEHEL Hydraulic

PEHEL Hydraulics We can service any brand of hydraulic pumps, motors, valves, hoses and other critical components of your hydraulic system. Contact us now. learn more about how we can keep your marine hydraulics in working order.