How do you tighten a JIC fitting?

For JIC flare fittings , it is crucial to collect the fittings inside the designed torque values a good way to Attain the designed pressure as according to SAE J514 standards. Below torque and over torque will result in Layout pressure loss.

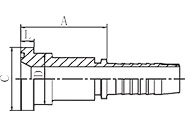

Connection Tube and JIC Fitting

Step 1:

take a look at on possible infection or harm on becoming surface and sealing floor. Reduce the tube. In keeping with the duration required and flare the tube head to a 37-diploma before set up.

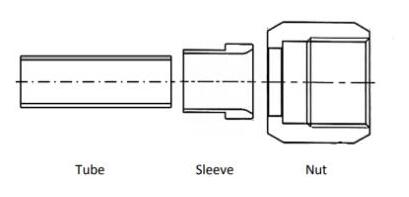

Step 2:

Apply lubricant inclusive of hydraulic fluid onto the threads and the complete floor of the flare.Step 3:

Insert the nut and sleeve onto the tube give up connection. Align additives for hand tightening anf turn the flare nut until sealing surface is completely contacted.Step 4:

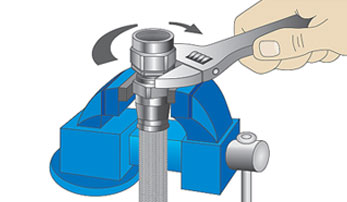

Test the tighten torque cost and make certain the sealing is attached as according to popular requirement.The fittings and tubing connection will be achieved with out external loads. Over tightening may also reasons. Deformation of 37-diploma flared of the male thread cease connection. Immoderate deformation of the flare

Will purpose in lack of clamping pressure and for this reason sealing loss.

Word: The fittings and tubing connection shall be accomplished without external hundreds. Over tightening may additionally.

Reasons deformation of 37-degree flared of the male thread quit connection. Immoderate deformation of the

Flare will cause in lack of clamping pressure and subsequently sealing loss.