One-Piece Hydraulic Hose Fittings vs. Two-Piece Hydraulic Hose Fittings

- As a hydraulic hose assemblies , do you ever get confused about which hose assembly to recommend to a customer? To begin, you must be familiar with your customers' equipment system, its working parameters, particularly the required working pressure, because as a distributor, you must ensure its safety using your hose assembly. You must also consider its service life and whether it is economical to your clients. It is the same as an end user.

When choosing a hydraulic hose fitting for a customer or for our own use, there are numerous factors to consider. However, we will only look at two aspects today:

1. What is the difference between a one-piece and a two-piece hydraulic hose fitting?

2. Which is more beneficial to the end user, and how does it perform?One-Piece Hydraulic Hose Fitting :

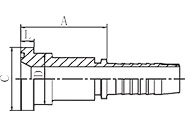

One-piece hydraulic hose fitting is an integrated hose fitting; in other words, the ferrule on the hose fitting is pre-crimped at the factory. Because of their advantages, one-piece hydraulic hose fittings are commonly used for basic applications and quick assemblies:> The ferrule would not move out of place.

> It is not necessary to spend much time selecting ferrules to match hose fittings.

> Distributors and end-users will save money and time.

Two-Piece Hydraulic Hose Fitting:

The most obvious advantage of two-piece hydraulic hose fitting is that it offers a wider selection of hose and fittings because the end-user can crimp hose assembly at their own facility. Of course, you must set up at least one crimping machine in your factory and stock enough fittings to meet various size and working pressure requirements.

> Large quantities of fittings, hose, and machine raise operating costs.

> With thousands of hose fitting sizes available, it is easy to make an installation error.

> Hose assembly of variable quality from various crimping machines.

Which is preferable to distributors and end users?

We can’t simply say which one is better, just analyze it from aspects of

1.final application,

2.identity as a distributor, repair shop, equipment supplier, etc.

3.cost factor.As an end-user, for an instance, you are a mine field company, the specification of the hydraulic hose fitting assembly you need for correlatively machines are limited, therefore from this point, one-piece fitting is more suitable.

If you are a distributor in local market, and your clients are from various industries, that would refer to many hose fittings standards, in that case, it is suggested you prepare sufficient stock for selection, two-piece will absolutely become the first choice.Installation time, downtime, whether a replacement hose fitting assembly could provide equal service life, and worker safety are all factors to consider as an aftermarket repair service or an equipment supplier.

We encourage our clients who received samples from us to conduct rigorous quality testing. Though the test could take up to three months to complete, this is the beginning of our true long-term business.

Quality testing should be conducted from three perspectives: 1. Sealing test: determine whether or not there is any leaking over a specified time period. 2. Hardness test: to see if the material can withstand environmental conditions. 3. Working pressure test: the impact of pressure surge on the hose assembly should be noted.

If you are interested in our hydraulic hose fittings , please contact our sales engineer to obtain the most recent catalog.