Hydraulic System Debugging

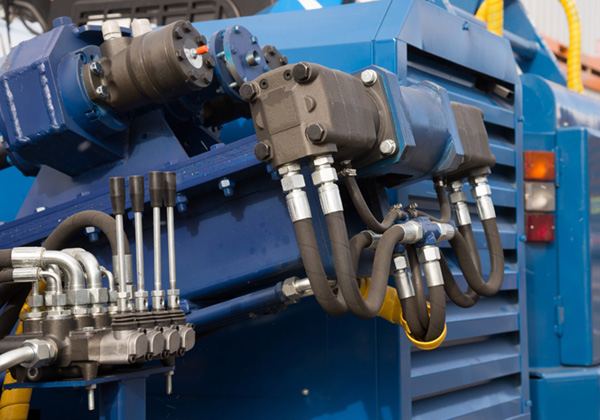

During the flow of hydraulic oil in the hydraulic system , the flow direction and flow of the liquid are unstable and difficult to predict, especially over long distances. The application of the pressure test point in the hydraulic system is helpful for the debugging of the system. And can improve the working performance of the system. Such a complex hydraulic system is difficult to debug and maintain. This feature should be fully considered in the design process, and every possible means should be used to improve and enhance the performance of the system.

1. Routine debugging of hydraulic system

The first is hydraulic pumps. Quantitative pumps are generally adjusted by overflow valves. Variable pumps generally have pressure adjustment and flow adjustment, which can be adjusted according to actual conditions.

The second is that the general hydraulic oil circuit will be equipped with an overflow valve at the beginning of the oil outlet to prevent excessive pressure from breaking the valve and other components to protect it. Generally, adjust this first. The value is higher than your hydraulic component. The work pressure is low, just higher than the required pressure.

The third is to adjust the pressure of your various circuits. There are pressure reducing valves, pressure relief valves, etc., and the pressure can be adjusted slowly according to the needs. If you use a proportional valve, you generally adjust the speed of the cylinder in and out. It can be produced according to production Efficiency to adjust.

2. The application of pressure test point is helpful to the adjustment of system pressure

In the conventional design, the oil pump outlet of the hydraulic system is equipped with a pressure gauge.

Due to the special characteristics of the hydraulic pipeline system such as long oil flow distance, liquid flow direction and flow rate change in the middle, the actual working pressure of the hydraulic motor and the outlet pressure of the oil pump may be far apart.

The pressure gauge is not only a measuring tool for adjusting the maximum working pressure of the oil pump outlet, but also a monitoring tool for the working pressure of the hydraulic system.

Through the oil pump outlet pressure gauge it is difficult to debug the actual working pressure of the hydraulic motor and the detection of the working pressure of the hydraulic motor, so the pressure adjustment when the hydraulic motor is working becomes very difficult.

And at the same time, it is impossible to make the hydraulic motor work under the appropriate pressure, which will inevitably affect the working performance of the hydraulic system and the working state of the hydraulic motor.

If a pressure gauge is installed directly at the oil inlet of the hydraulic motor, although the working pressure of the hydraulic motor can be measured, it will increase the cost of the hydraulic system. Moreover, the choice of the installation position of the pressure gauge, as well as the working environment and service life are all difficult to guarantee. If a pressure test point is installed at the oil inlet of a hydraulic motor, the situation is different.

Since the pressure test point is very close to the hydraulic motor, the pressure measured basically reflects the working pressure of the hydraulic motor, which will help the accurate adjustment of the working pressure of the hydraulic motor. At the same time, the cost of the pressure test point is relatively low, the installation location is easy to choose, it is not restricted by the working environment, and the service life is long.It can completely avoid the various problems of installing the pressure gauge at the oil inlet of the hydraulic motor.

3. The application of pressure test point helps to improve the working performance of the system

Hydraulic shock is inevitable in the process of hydraulic work, and hydraulic shock is very harmful to the normal operation of the hydraulic system. Avoiding or reducing hydraulic shock as much as possible is a problem that must be considered in the hydraulic system design process.

There are many reasons for the hydraulic shock, including the sudden change of the liquid flow direction and the mixing of air bubbles in the hydraulic oil. Then we can fix the pipe by using the hydraulic pipe clamp to avoid severe vibration, and set the air bubble filter metal mesh in the oil tank. And by extending the distance of the liquid flowing in the tank to make the bubbles gradually seep out, try to avoid the sudden change of the liquid flow direction.

Therefore, it is a good choice to install a pressure test point in the hydraulic pipeline. The pressure test point can be used to release the gas gathered in the higher part of the hydraulic pipeline, so as to compensate for the low rate of bubble leakage in the oil tank and reduce hydraulic shock. It is very beneficial to improve the working performance of the system.

Proper application of pressure test points in hydraulic systems often does more good than harm. Very useful for troubleshooting, debugging and performance improvement of hydraulic systems.

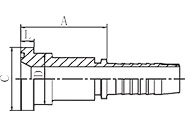

If you need to purchase hydraulic systems, Hydraulic hose fittings , adapters to oil block , crimping machines or Hydraulic manufactures, please contact us . Or visit our website:https://www.pehelhydraulic.com/contact.html