How to use hose fittings

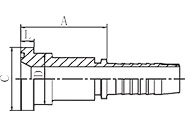

Hydraulic fittings connect conductors such as hoses, pipes and tubes in a hydraulic system . Most fittings have a male and female component that join to form a connection. These connections help contain and direct the flow of hydraulic fluid in the conductor while preventing leaks and maintaining pressure. Different fittings allow designers to change flow direction, the elevation of lines or split flow. Crimping is the most common method for assembling hoses and fittings. Once the crimp specifications have been checked for the specific hose and fitting, a crimping machine is adjusted to the appropriate crimping diameter setting. The next step is to lubricate the fitting, put it on the end of the hose, and then put it in the crimping machine .

Some companies offer no-skive option on their hoses. Skiving refers to a process where part of the hose cover or even the inner tube is removed before a hose end is attached. No-skive hoses do not require this step. Many prefer no-skive options because it makes hose assembly quicker and reduces the risk of hose damage during crimping.

Fitting geometries include crosses, plugs, elbows and others. It’s important to pay attention when identifying the threads of the connections. Often, connections from one standard appear to thread into another standard port but do not have enough engagement to be safe. Furthermore, most fittings are brand-specific for certain hoses and may not work with other brands. While fitting dimensions often correspond to the size of the conductor there can still be a variance in fitting options for one size of pipe or tube.

Fittings are made of many different materials including stainless steel, brass, plastic. Not always, but often fittings match the material of the conductor used in a system. This multitude of materials creates fittings with a wide array of performance capabilities. Most hydraulic fittings have designated pressure and temperature ratings as well as size and dimension standards set by the SAE.